Indian maize has emerged as a preferred choice for international importers across food processing, animal feed production, and industrial applications. Moreover, as one of the world’s largest maize producers, India offers unique advantages that make it an attractive sourcing destination for discerning buyers worldwide.

India’s Competitive Edge in Global Maize Markets

India ranks as the 5th largest maize producer globally and the 14th largest exporter, with a strategic advantage that sets it apart from major competitors. Unlike Argentina, Brazil, and the United States, India specializes in non-GMO maize production, addressing the growing global demand for genetically modified-free agricultural commodities.

Furthermore, European markets, including Germany, Netherlands, and Belgium, specifically seek non-GMO corn for their stringent food safety requirements. Japan and other Asian markets similarly prioritize non-GMO grains for their food processing industries. As a result, this positions Indian maize in a distinct market segment with premium pricing potential.

Superior Quality Standards and Specifications

Specifically, Indian exporters maintain rigorous quality control measures that ensure consistent, export-grade maize. Standard specifications include:

- Moisture content: 14% maximum

- Protein content: 8% minimum

- Aflatoxin levels: 20 PPB maximum

- Broken kernels: 3% maximum

- Impurities: 2% maximum

- Weevil damage: 2% maximum

Consequently, these specifications meet international standards for food-grade and feed-grade applications, ensuring reliability for importers across diverse end-use sectors.

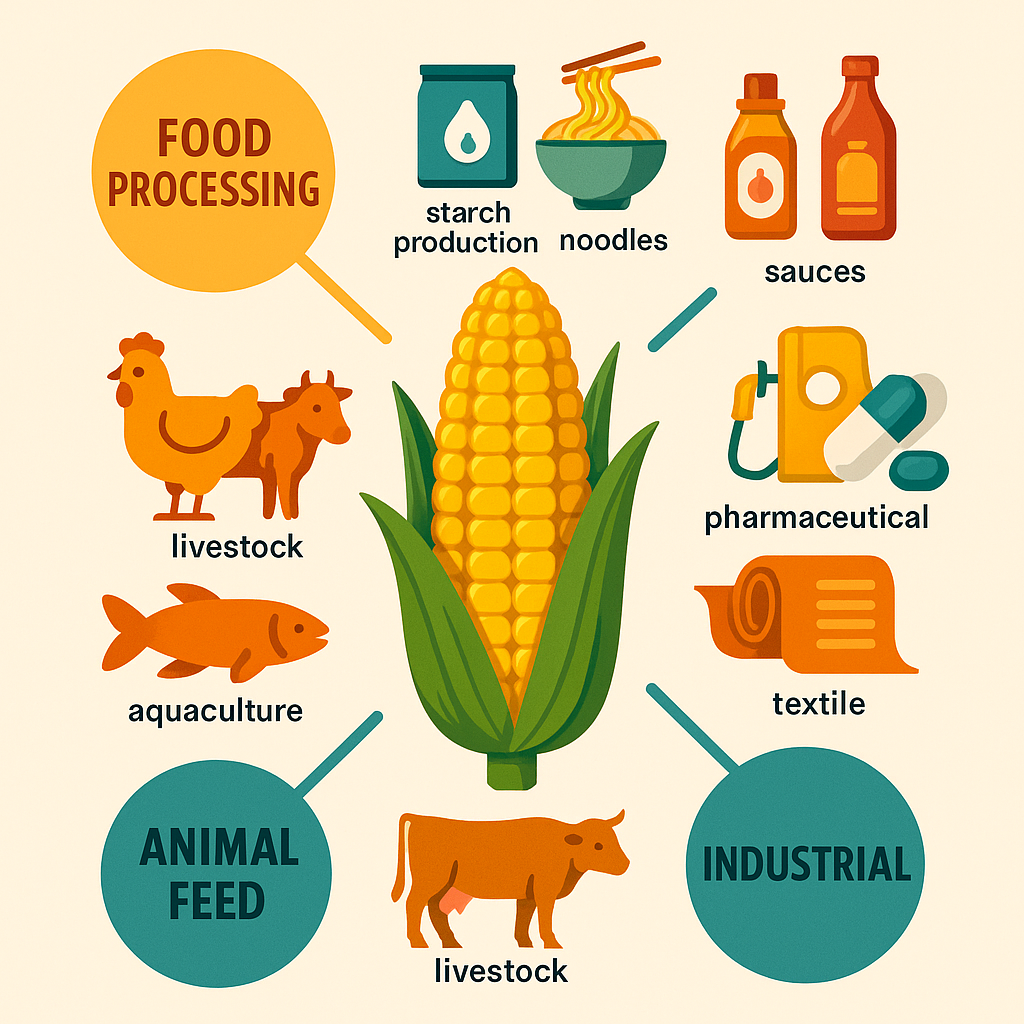

Diverse Applications Across Industries

Food Processing Industry

Indian maize serves multiple applications in food manufacturing:

- Starch production for noodles, sauces, and baked goods

- Corn flour for ready-to-eat and packaged foods

- Sweeteners and syrups for beverage production

- Breakfast cereals and snack food manufacturing

For instance, Malaysian food processors utilize Indian maize for canned foods, instant products, and Asian beverages. Therefore, the consistent quality and competitive pricing make it ideal for high-volume manufacturing operations.

Animal Feed Production

In addition to food processing applications, the livestock and aquaculture sectors rely heavily on Indian maize for:

- Poultry feed formulations for broilers and laying hens

- Livestock nutrition for cattle and swine

- Aquaculture feed for fish and shrimp farming

- Pet food manufacturing

Indian yellow maize provides high caloric content essential for animal growth and production efficiency. The hard kernel structure and optimal nutritional profile make it particularly suitable for tropical climate storage.

Industrial Applications

Beyond food and feed, Indian maize supports various industrial processes:

- Ethanol production as a renewable fuel source

- Pharmaceutical grade starch for medical applications

- Textile industry for sizing and finishing processes

- Paper and packaging industry applications

Strategic Packaging and Storage Solutions

Food Industry Packaging

For food-grade applications, Indian exporters utilize:

- Multi-wall paper sacks with plastic liner bags for moisture protection

- Similarly, Laminated pouches with metallized barriers for extended shelf life

- Composite containers with PE-coated foil for premium products

- Flexible packaging with center-seal or three-side seal formations

Each package includes comprehensive labeling with nutritional information, origin details, and batch traceability codes.

Feed Industry Packaging

On the other hand, animal feed applications require robust packaging solutions:

- 50 kg polypropylene bags for easy handling and storage

- 25 kg bags for smaller operations and specialty feeds

- Bulk containers for large-scale feed manufacturers

- Moisture-resistant materials to prevent spoilage during transport

Industrial Bulk Supply

Alternatively, large-scale industrial users benefit from:

- Container loads of 20-24 MT capacity

- Specialized bulk handling systems for efficient loading

- Custom packaging based on specific industrial requirements

- Quality segregation for different industrial applications

Advanced Storage and Preservation Methods

To ensure optimal quality preservation, Indian maize exporters employ sophisticated storage techniques to maintain quality:

Climate-Controlled Facilities

- Temperature management between 18-20°C optimal storage

- Humidity control maintaining 12-14% moisture levels

- Ventilation systems preventing condensation and mold

- Pest management through integrated control measures

Quality Preservation Technology

- Fumigation treatments eliminating storage pests

- Modified atmosphere storage reducing oxygen levels

- Regular quality monitoring through sampling and testing

- Traceability systems ensuring batch integrity

Efficient Shipping and Logistics

International Transportation

Strategically located, Indian ports offer excellent connectivity for global markets:

- For example, Mundra and Kandla ports for Middle East and European markets

- Similarly, Nhava Sheva (Mumbai) for Southeast Asian destinations

- Chennai and Visakhapatnam for Far East markets

- Specialized bulk carriers for large volume shipments

Documentation Excellence

To ensure smooth customs clearance, complete export documentation includes:

- Phytosanitary certificates from Indian plant protection authorities

- Quality test reports from accredited laboratories

- Fumigation certificates for pest-free shipments

- Certificate of origin for trade agreement benefits

Year-Round Supply Reliability

India’s diverse agro-climatic zones enable continuous maize production:

- During the Kharif season (June-December) in Maharashtra, Karnataka, and Madhya Pradesh

- Subsequently, during the Rabi season (December-May) in Gujarat, Rajasthan, and Punjab

- Additionally, the Summer crop in irrigated areas ensuring consistent availability

- Multiple harvests providing steady supply throughout the year

As a result, this production cycle ensures importers can rely on consistent sourcing without seasonal disruptions.

Cost Competitiveness and Value

Indian maize offers exceptional value through:

- Lower production costs due to favorable farming conditions

- Competitive freight rates from well-connected ports

- Bulk supply capabilities reducing per-unit costs

- Long-term contract options providing price stability

The cost advantage, combined with quality assurance, makes Indian maize highly attractive for cost-conscious importers.

Sustainability and Organic Options

In addition to cost benefits, Growing demand for sustainable agriculture drives Indian exporters to offer:

- Organic certified maize for premium markets

- Sustainable farming practices reducing environmental impact

- Non-GMO certification meeting strict European standards

- Traceability programs ensuring supply chain transparency

Partner with Trusted Indian Exporters

Given these advantages, are you Ready to source premium Indian maize for your operations?

Clearly, Indian maize exporters offer comprehensive solutions for food processors, feed manufacturers, and industrial users. With this in mind, proven expertise in quality assurance, efficient logistics, and reliable supply chains, Indian suppliers deliver consistent value to international partners.

Therefore, contact established Indian maize exporters today to:

- Request detailed product specifications and pricing

- Arrange quality samples for evaluation

- Discuss customized packaging and shipping solutions

- Establish long-term supply partnerships

Transform your sourcing strategy with Indian maize – where quality meets competitive pricing, and reliability ensures your business success.

Ready to explore Indian maize sourcing opportunities? Connect with Patil More Exports who understand your industry needs and deliver consistent quality you can trust.